|

The

Restoration of an American Work of Art

The McCormick-Deering No. 7 Mower

By Chris Tramel

There

is an inherent beauty to the old farm machinery used by so

many generations. There is something about the sight of an

old rusty hay rake sitting in an open field, or a long abandoned

mowing machine with honeysuckle growing up the cutter bar,

that just begs to be photographed and framed. It is a reminder

of days long gone, a time when agriculture dominated the economy,

and whole families made their living from the fertile land.

But

there was so much more to these wonderful machines. As a child,

I was always fascinated by the integrate mesh of gears, and

chains, and blades, that were combined to form something that

looked like it belonged in a Jules Verne novel. Surely if

you combined these machine with some mysterious power you

would materialize in some other time or dimension. But

there was so much more to these wonderful machines. As a child,

I was always fascinated by the integrate mesh of gears, and

chains, and blades, that were combined to form something that

looked like it belonged in a Jules Verne novel. Surely if

you combined these machine with some mysterious power you

would materialize in some other time or dimension.

As with

so many children of the farm, the first time being behind

the wheel of any vehicle was in the seat of my grandfather's

Super A Farmall tractor. As there are loyalties in the automotive

world, i.e. Ford, Chevy, Dodge ... there was also loyalty

amongst the farming community. There were green farmers, and

blue farmers, but we were always red farmers. International

Harvester was our equipment of choice.

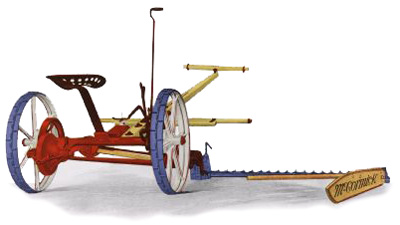

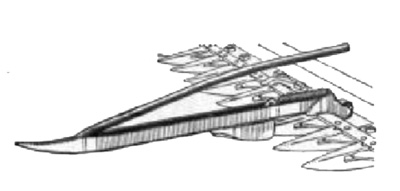

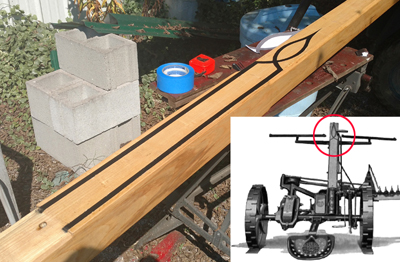

Notice

the grass board logo and striping on the tongue

International

Harvester Company, was formed August 12, 1902, by the merger

of the McCormick Harvesting Machine Company, Deering Harvester

Company, Milwaukee Harvester Company, Plano Harvester Company,

and Warder, Bushnell & Glessner Company. Cyrus H. McCormick

Jr. was named president of the board, while Charles Deering

was named the chairman.

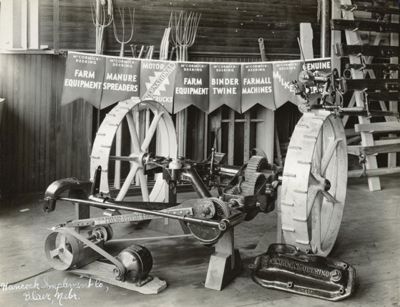

In 1911,

the company began producing implements such as mowers, rakes

and fertilizer spreaders under the McCormick name. The McCormick-Deering

line of mowers included the No. 6 Plain Mower, No. 6 Vertical

Lift Mower and Big 6 Mower. In following years, the company

produced the McCormick-Deering No. 6 Plain Lift Mower.

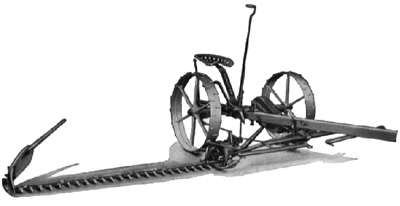

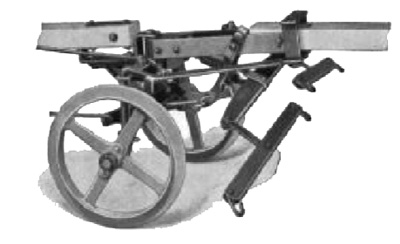

A

No. 6 McCormick mower - Blue seat and spring and white bars

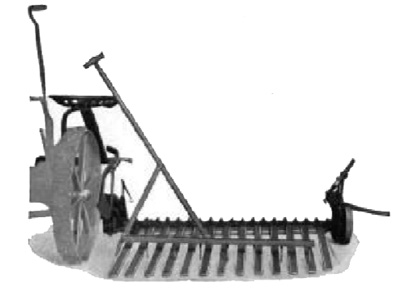

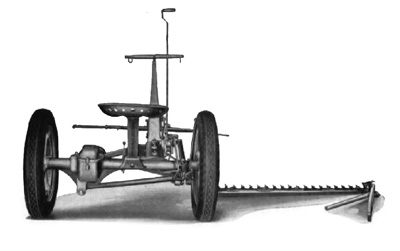

Horse-drawn

mowers were generally designed with a series of gears that

would power a mower bar. As the wheels turned, they would

turn several gears which would turn a flywheel. The flywheel

would move a wooden pitman arm back and forth, which was connected

to the mower bar. The mower bar consisted of a set of knives

or blades, that would move back and forth between a set of

guards. The guards, fitted with serrated plates known as ledger

plates, would act in a scissor action with the knives, cutting

grass and other foliage.

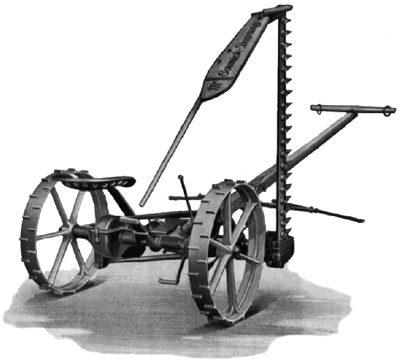

No 6 Mower

In 1929

the company introduced an improvement in the horse-drawn mowers

with the No. 7 Regular Lift, No. 7 Vertical Lift, and Big

7 Regular Lift. The No. 7 was the first enclosed gear mower,

which meant the gears were housed in a gear box with a bath

of oil continuingly lubricating the works. Think of a differential

or rear end under a truck or car. Before the No. 7, mowers

were an open gear design, meaning the user would constantly

have to stop and manually oil the drive gears on the inner

wheels.

The main

axle is made in two sections (one long and one short shaft)

with the pawl-and-ratchet devices placed at the junction of

the two sections inside the gear case, similar to the differential

arrangement on an automobile. Placing the pawls and ratchets

in this location protects them from dust and undue wear and

assures proper lubrication at all times. The axle revolves

in four roller bearings (two single and two double) which

are encased in steel sleeves that can be replaced when worn.

The bearings are automatically oiled from the gear case and

require no attention. Leather oil seals enclosed in metal

cases prevent oil from leaking past the ends of the axle.

The mower wheels are keyed solidly to the axle sections, eliminating

end play, wobble, and lost motion.

The Plain

Lift Regular No. 7 and Combination Regular No. 7 (which could

be converted to a plain lift or vertical lift cutter bar)

came with the option of two bar sizes, a 4-1/2 foot and a

5-foot mower bar, while the Plain Lift Big 7 offered bar sizes

from 4-1/2 to 7-foot. The Combination Big 7 had bar sizes

of 4-1/2 and 5-foot. The weight of the Regular No. 7 ranged

between 770-780 pounds, depending on bar size, while the Big

7 weighed between 835 and 860 pounds. The Combination No.

7 weighed between 780 and 790 pounds, while the Combination

Big 7 weighed between 845-850 pounds. Big 7 mowers have heavier

and wider rim wheels than the Regular No. 7. Pneumatic-tired

wheels could also be obtained at extra cost for any size of

No. 7.

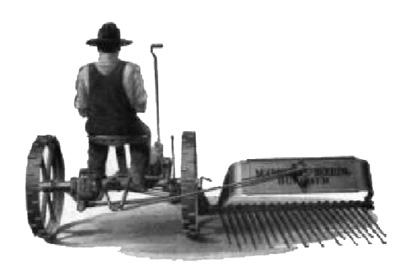

The vertical-lift

mowers possess the feature of having both vertical and plain

lift and can be changed instantly from one to the other by

merely shifting a lever. The plain-lift mowers do not have

this combination-lift feature. Vertical-lift mowers permit

raising the cutter bar to a full vertical position without

stopping the mower or leaving the seat. This mower has a high

horizontal lift for passing over trash and stones and a full

vertical lift that swings the bar out of the way of high obstructions.

Either type of lift is instantly available by merely moving

a small lever.

The

No. 7 came with regular equipment, which included a tongue,

neckyoke, steel doubletrees, knives and ledger plates, a combination

wrench, and oil can. Additional accessories were also available,

including: The

No. 7 came with regular equipment, which included a tongue,

neckyoke, steel doubletrees, knives and ledger plates, a combination

wrench, and oil can. Additional accessories were also available,

including:

Reaping

attachment for 4-1/2 and 5-foot sizes

Buncher attachment for 4-1/2, 5, 6, and 7-foot sizes

Weed attachment

Two-wheel tongue truck

Pea and bean vine lifters (set of six including outer

shoe runner)

Lespedeza bars (4-1/2, 5, and 6-foot)

Weed and brush bar, 3-1/2, 4, 4-1/2, and 5-foot cutting

widths

Weed bar, 3, 3-1/2, 4, 4-1/2, 5, 6, and 7-foot cutting

widths

Mower pea bar attachment (5-ft.)

Pneumatic tired wheels

Stub pole tractor hitch (for hitching mower direct to

tractor)

Steering pole or trailer hitch (for hitching trailing

mower behind tractor mower or for hitching second of two

mowers to tractor)

Knives with under-serrated sections

Smooth ledger plates.

Heavy-Duty

Bar - This bar was substantially constructed

for heavy work and cutting over rough, stony ground. It

had heavy-type guards and was supplied with heavy knives.

Guards have the same spacing as on regular mower bar, but

are larger and heavier and make continuous contact at the

base. Heavy-Duty

Bar - This bar was substantially constructed

for heavy work and cutting over rough, stony ground. It

had heavy-type guards and was supplied with heavy knives.

Guards have the same spacing as on regular mower bar, but

are larger and heavier and make continuous contact at the

base.

Weed

Bar - This bar was designed for cutting heavy

weeds, light brush, etc. It had heavy, blunt guards that

have no lips. This feature permits cutting woody stems and

stalks with less draft and likelihood of choking. A heavy

knife was supplied.

Lespedeza

Bar - A low-cut bar with steel double guards

of special type having 1-1/2-inch spacing. Designed especially

for cutting Lespedeza and other crops where an extremely

low cut is desired. Steel guards have no ledger plates.

Knife with under-serrated sections were supplied.

Reaper

Attachment - A reaping attachment for cutting

grain and special seed crops could be supplied for use with

all McCormick-Deering mowers having 4-1/2 and 5-foot cutter

bars. The attachment included an extra seat over the right

wheel for the operator, who reels the crop onto the platform

with a rake and retains it until a gavel of the right size

is secured, then dumps it off upon the ground.

Buncher

Attachment - This attachment was designed for

gathering very short hay, which could not be raked easily.

It was used also for gathering seed crops. The hay is gathered

upon the slatted platform back of the cutter bar, and when

a sufficient amount has accumulated, the driver dumps it

by raising the shield. This was accomplished with a foot

lever. Buncher attachments could be furnished for 4-1/2,

5 and 6-foot mowers.

Mower

Tongue Truck - Under certain conditions owners

sometimes preferred to equip their mowers with a tongue

truck. The tongue truck reduces side draft and takes the

neck weight off the horses. The truck was provided with

a casting permitting the attachment of a draft rod running

from the inner shoe hinge on the cutter bar to the tongue

truck. The tongue truck could be supplied with a long pole

and stub pole, or could be supplied without either pole

when so ordered.

Vine

Lifters - Used when cutting matted grass, vines,

etc., also on binders for lifting lodged grain. The lifters

fit over the guards and are bolted individually in place.

Upper bar vibrates and clears itself of vines.

Weed

Attachment - McCormick-Deering mowers could

be equipped with a weed attachment which holds the cutter

bar off the ground at a sufficient height to avoid stones

or to pass over a young crop of grain. The attachment consists

of an adjustable hook which supports the inner end of the

cutter bar and a wheel for supporting the outer end of the

cutter bar above the ground. Both ends are adjustable so

that the cutter bar can be raised to any height up to 12

inches.

Canning

Pea Mower Bar Attachment - This bar is made

especially for harvesting green peas for canning. The bar

is regularly equipped with pea vine lifters (set of six),

pea vine divider, and windrower fingers. The pea vine lifters

are of special design, smoothly finished, and streamlined

to give the most efficient action. The lifters are hinged

so that the points follow the contour of the ground closely,

picking up all the vines and raising the pods above the

sickle so that none will be cut or wasted. The windrower

is designed so that the vines are rolled gently into windrows,

with the pods inside and the vines and stems on the outside.

This prevents the pods from drying out and keeps the peas

fresh. The windrow is deposited at the rear, out of the

way of the horses or tractor wheels on the following round.

No.

7 Pneumatic-Tired Mower - For cutting weeds

and grass along the shoulders of hard-surfaced roads, the

No. 7 mower could be equipped with pneumatic-tired wheels

for highway use. Pneumatic tires provided efficient traction

on paved or hard-surfaced roads and made a comfortably riding

machine for the operator. The tires are balloon type, 5.25

x 21-inch size, mounted on conventional automobile-type

rims which fit over the wheel spokes and are secured by

locking lugs. This makes removal of the tire as simple as

the removal of an automobile tire. The wheels have special

split type hubs and are clamped tightly around the axle

by four bolts. In addition, the wheels are keyed to the

axle, eliminating all likelihood of wobble and end play.

The No. 7 pneumatic-tired mower was available in 4-1/2,

5, 6, and 7-foot sizes. The equipment was same as for the

standard No. 7 mower. Weight, deduct 90 lb.

In 1939,

the company improved the design again with the No. 9 mower.

This design moved the gear box back a bit, giving the machine

better balance and reducing the pole (tongue) weight. This

design would last until the end of horse drawn mower production.

The last year for the No. 9 mower was 1951.

Was

There a No. 8 Mower?

While

production reports from McCormick-Deering do not list a No.

8 mower, apparently they do exist. I have found no documentation

about a No. 8 mower, however I have seen several post and

photos of No. 8s. They were very similar to a No. 7 mower,

but what looks like a casting over the gear cover to allow

for a larger gear. There is also no casting for the oil can

holder.

According

to some sources, the No. 8A was an export model out of McCormick-Deering's

German site, at Neuss on the Rhine, near Dusseldorf. Production

of implements under the McCormick brand name started there

in 1911 with the typical products being, mowers, rakes and

fertilizer distributors.

By the

time the Nazis came into power, high taxes and tariffs on

imports made it difficult for companies outside of Germany

to make a profit. The company was also forbidden from exporting

their German marks, so in 1936 McCormick-Deering dropped farm

implements at the Neuss factory and began making the more

profitable tractors full time.

Another

thing that may have contributed to the lack of information

about the No. 8 mower is the fact that 70 percent of the McCormick-Deering

factory in Germany was destroyed by Allied bombing during

WWII. For anyone with additional information on these, it

would be appreciated if you would share your knowledge.

Paint

Schemes for McCormick-Deering Mowers

Mowers

seemed to have a varying color scheme early on, with the general

rule that the main body be red, the cutter bar blue, and the

wheels white (or more specifically cream). Seats and springs

may have been painted red or blue, while some connecting bars

may have been red or white.

In 1927,

a Paint Committee was formed by the company to create a standardized

color scheme for different equipment, which would effect the

McCormick No. 6 Mower - 1916-1933, the McCormick-Deering No.

7 Mower - 1929-1939, and the McCormick-Deering No. 9 Mower

- 1939-1951. While the committee was formed between the No.

6's production years, these mowers could have varying color

schemes depending on when the mower was made.

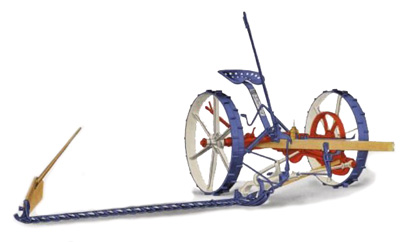

The correct

colors for a No. 7 mower would be an oil based Harvester Red

on the main body and all levers, seat, and seat spring, while

the mower bar, guards, and outer wheels are a blue enamel.

The inner wheels should be Harvester White (which is actually

a cream or almond color), while the pole (tongue), evener,

and tracker (grass board) is ochre (a burnt orange color).

The tracker rod (the rod extending from the grass board) is

a natural finish, while the pitman rod should be boiled in

oil. All ironworks attached to the pole and evener should

be Indian Red. The wrench that comes with the mower should

be blue, while the oil can should be white with the McCormick-Deering

logo, bordered with red and blue stripes at the top and bottom.

Lettering on the tracker should say "McCormick-Deering"

in Indian Red, with a red strip running along the top. The

pole should also have decorative striping in black running

from each side and crossing across the top just past the doubletrees.

The same

color scheme is used on the No. 9 mowers (1939) except the

blue paint was eliminated from he outer wheels and the striping

was discontinued. The cutter bar was also changed from blue

enamel to blue lacquer.

In June,1940

the seat spring, pawl holders, and eveners were painted blue,

but later that same year the eveners were changed to Indian

red.

The following

is on record at the Wisconsin Historical Society's McCormick-Deering

archives:

"RED,

WHITE, AND BLUE" PAINT COLOR SCHEME

The

Paint Committee was appointed by Mr. Alex Legge for the

purpose of establishing a channel through which any changes

in the painting of the Harvester Company's products may

pass. Now that the Company is on the one-line basis, and

the entire product in the United States and Canada is sold

under the name "McCormick-Deering" (motor trucks

excepted), it is desirable to establish a uniform paint

program for three purposes:

First—To

improve the quality of the painting

Second—To

standardize the color scheme on all lines so that they will

be distinctive, harmonious, and attractive in appearance

Third—So

that machines of similar style or general appearance will

be painted alike, even though they are made at different

Works

The

Paint Committee has tried out various combinations of colors

on different machines and has finally decided on a red,

white, and blue program for the general line of farm machines,

excluding motor trucks, tractors, engines, cream separators,

wagons, and sleighs.

The

following Works are affected:

McCormick

Deering

West Pullman

Auburn

Rock Falls

P & 0 Plow

Richmond

Chattanooga Plow

Hamilton

While

in a general way this new color scheme is to be known as

a "red, white, and blue" program, cream will be

used instead of white, and other supplemental colors will

be employed. The following explanations will apply in a

general way to all machines affected by specific Paint Committee

decisions to be issued later:

Harvester

Red

Harvester Cream

As

a general rule, Harvester red will be the dominating color

and will be applied to the main parts of the machines.

Harvester

cream will be used on all ground wheels unless otherwise

specified and on certain parts of some machines where the

employment of this color will tend to lighten the appearance

of the machine.

-

- - - - - - -

January

14, 1927

Paint Committee Decision No. 34

MOWER

Harvester

Red - Frame, tilting lever, raising lever, foot

lever, raising lever quadrant, seat and seat spring, and

rods not otherwise specified

Harvester Cream - Wheels

Harvester Blue - Cutter bar and facing

on wheels

Indian Red - Ironing on pole and evener

Ochre - Pole, evener, and tracker board

Natural Wood - Track clearer stick

Boiled in Oil - Pitman

-

- - - - - - -

January

9, 1939

Paint Committee Decision No. 112

DISCONTINUING

BLUE COLOR ON RIMS OF MOWER WHEELS

McCormick Works Product

The

cost of painting the outside of the rims of mower wheels

blue has amounted to a total of $2,117.40 on the manufacturing

order of 98,000 mowers the past year. As there seems to

be no special benefit in painting these wheel rims blue

it has been decided to discontinue this and to dip the entire

wheel in a cream color. Effective from the date of this

decision McCormick Works will dip all mower wheels in cream

and eliminate the blue color on the outside of the rim.

-

- - - - - - -

Paint

Committee Decision No. 113

DIPPING ALL MOWER BARS IN BLUE LACQUER

McCormick Works Product

It

is now the practice of the McCormick Works to paint mower

bars in three different ways. The Lespedeza bar is blue

lacquer, power-driven mower bars are dipped in clear varnish,

and horse-driven mower bars are dipped in a blue enamel.

The suggestion comes from the McCormick Works that in the

future they be permitted to paint all mower bars by dipping

them in a blue lacquer.

As this will result in a considerable saving in the manufacture

of mowers, the Paint Committee authorizes the McCormick

Works from this date to paint all mower bars by dipping

into blue lacquer.

-

- - - - - - -

June

23, 1939

Paint Committee Decision No, 117

The

cost reduction committee at McCormick Works has made the

following recommendations:

2.

That the striping be left off from mower tongues and grass

boards. The striping on the mower tongues consists of a

decorative design in black. The same tongue when shipped

out for repairs is not striped. The striping on grass boards

consists of one dark red stripe along the top edge. If this

striping is eliminated, a saving of $726.40 can be made

on the annual manufacturing order.

The

Paint Committee hereby approves the use of red paint only

on the A frame of ensilage cutters, the elimination of striping

on mower tongues, grass boards, and on the gatherer boards

of one-row and two-row vertical corn binders.

-

- - - - - - -

June

21, 1940

Paint Committee Decision No. 128

McCORMICK-DEERING NO. 9 MOWER

McCormick Works Product

This

machine will be painted in the following colors:

Harvester

Red - Frame and all parts except wheels, pole, neckyoke,

grass board, grass stick, cutter bar, seat spring, lifting

spring, pitman, pawl holders, and eveners.

Harvester Blue - Seat spring, lifting spring, pawl holders,

and eveners.

Harvester Cream - Wheels

Harvester Ocher - Pole, neckyoke, grass board, and grass

stick.

Natural Wood Varnish - Pitman

Blue Lacquer - Cutter bar

It

is agreed that the frame and other parts painted in Harvester

red will receive one coat only.

-

- - - - - - -

September

26, 1940.

Paint Committee Decision No. 128

McCORMlCK-DEERING NO. 9 MOWER

McCormick Works Product

This

machine will be painted in the following colors:

Harvester

Red - Frame and all parts except wheels, pole, neckyoke,

grass board, grass stick, cutter bar, seat spring, eveners,

pitman, and pawl holders.

Harvester Indian Red - Eveners

Harvester Blue - Seat spring, pawl holders

Harvester Cream - Wheels

Harvester Ocher - Pole, neckyoke, grass board, and grass

stick

Natural Wood Varnish - Pitman

Blue Lacquer - Cutter bar

It

is agreed that the frame and other parts painted in Harvester

Red will receive one coat only. This cancels Paint Committee

Decision No, 128 of June 21, 1940.

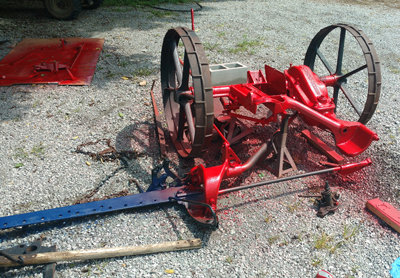

Our

No. 7 McCormick-Deering Mower

I purchased

this old machine from my neighbor 20 years ago. He was a man

that had made his living on a farm his entire life and had

never owned a tractor. His entire career was horse drawn,

and as he went into his 90s he decided it was time to retire.

Our

machine had long since retired, and I had to cut a couple

of cedars to free it from its resting place. I actually bought

two of these from the farmer, and this one was in the worst

condition.

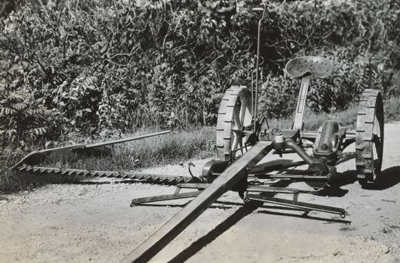

I

bought another No. 7, one that the farmer had been using when

he retired. This one is in working condition, though not very

pretty. Notice the tires? No, this is not the model with pneumatic

tires. In areas where there a lot of rocks, like here in Middle

Tennessee, farmers would cut up old tires, fold them over

the steel wheels, then lace them together. It wouldn't give

you the ride real tires would offer, but it would offer a

little smoother and quieter ride.

Here

I'm beginning to clean off the rust and apply an under coating.

The machine will get a new front seal, new guards and ledger

plates, knives, pitman, grass board, seat, and tongue.

Pole

Length and Wood Type

The pole

or tongue lengths for these mowers are generally 14 foot in

total length. With the mower setting low to the ground, the

team needs forward room for clearance. Some have said that

they use a 12-foot pole, and this is okay depending on the

size of your team. Remember that the tongue sits 15 inches

inside the cast iron mount. Plus, draft horses today are a

lot larger than the teams our grandfathers used.

Another

consideration is the type of hardwood used for the tongue.

Oak and ash are some traditional choices, but new ash is currently

quarantined from being cut due to green beetle infestation

and the tree is endangered. White oak is a strong wood that

is weather resistant, but is very heavy. The No. 7 is already

tongue heavy and trucks might be considered if you use oak

to help relieve the neck weight from the horses.

For my

tongue I have chosen sassafras. Sassafras is very weather

resistant, nearly as strong as oak, but best of all, it is

light in weight. If you can find it available, it makes an

excellent choice for the pole and grass board. Here I have

had a 16-foot straight-grained piece of sassafras cut from

the sawmill, five inches square at one end and tapered down

to three inches at the front end. Don't start the taper for

maybe two or two and a half feet from the large end (remember,

the tongue needs to be squared on the sides in the mount.

The reason

I have the tongue longer and wider than I need it, is because

it is green. It will be stored in the hayloft of my barn to

season. Wood will shrink in width as it dries. It will only

shrink across the grain, not the length of the wood. It was

cut a couple of feet extra in length to allow for any splitting

that may occur as it dries. Once cured, I will trim the tongue

to the appropriate size.

Changing

the Front Seal

While

the mower is apart for paint, it's a good idea to change the

front oil seal located behind the flywheel. After opening

up the top cover, I found all the gears surprisingly in wonderful

condition. There are no chipped teeth on the gears or signs

of wear, however the front seal had seen better days.

Removing

the front seal is not complicated, but does take some finesse.

First, remove the pitman and bearing from the flywheel, then

inside the main gear case take a small piece of wood and wedge

it between the two large gears to keep the mechanism from

turning.

Once this

is done, take a hammer and another piece of wood (I used a

scrap 2x2) and lightly tap the drive gear on the front shaft.

DO NOT HIT METAL ON METAL! The gear will turn in the same

direction that the flywheel turns when in operation. Do not

try to force it as the teeth on the gear can break. Remove

the wood wedge and turn the mechanism a little, then tap again

on a different gear tooth. Patience is key. Repeat this process

until the gear breaks free of the shaft. Once free, the gear

will simply screw off the rest of the way.

The procedure

is the same for a No. 9 mower, however be aware that on this

model there is a washer on the shaft located between the gear

and housing. If you pull the shaft out without removing the

washer, it will drop into the oil reservoir and will be very

frustrating to try to retrieve.

The oil

seal is not a mysterious item that is no longer available.

It's a simple oil seal that can be acquired at your local

auto parts store. The number for the original seal will cross

to two different oil seals, one large front to back and one

skinny. The large one is the one that fits, though either

will work.

Making

the Tracker (Grass Board)

As with

most antique mowers, the grass board is long gone. The tracker

consists of a wooden paddle-shaped board, mounted to a metal

side plate. The metal plate allows for a bolt and spring to

attach the tracker to the cutter bar. The spring gives the

board some play should it hit some obstacle.

The

underside of the tracker has a metal strip running the entire

length of the board, and a small vertical metal support strip

on the outer side. On the inside of the board is the tracker

rod or grass stick. It is attached with a metal cover and

two bolts. The rod pivots on one bolt, while the other enters

one of three holes in the board, allowing it to be adjusted

in height. Ours is made of sassafras and will be painted with

the correct logo and stripe. The

underside of the tracker has a metal strip running the entire

length of the board, and a small vertical metal support strip

on the outer side. On the inside of the board is the tracker

rod or grass stick. It is attached with a metal cover and

two bolts. The rod pivots on one bolt, while the other enters

one of three holes in the board, allowing it to be adjusted

in height. Ours is made of sassafras and will be painted with

the correct logo and stripe.

- - - - - - - - -

The

red, white, and blue scheme is starting to take shape. The

lacquer paint

takes a long time to dry. Putting a few coats on.

Down

to the Nuts and Bolts of the Project

Like

most machines made during the 1920s and 1930s, the No. 7 mower

has a lot of square head bolts and nuts. There are some hexagon

nuts on the machine, such as the guard nuts and the nuts on

the wheel bolts, but the majority are the old style square

bolts.

Painting

the original square head wheel bolts and hex nuts

Contrary

to belief, you can still buy brand new square head bolts and

nuts. Just because you can't find them at Lowes or Home Depot

doesn't mean that they are no longer made. It just means that

the big box stores don't sell enough of them to justify stocking

them.

A

brand new square head nut and bolt for the seat spring. The

original

was too far gone, with the seat spring mount being an area

that collects

water, and had to be cut off with a grinder.

Luckily

for restorers in this day and age we have a wonderful resource.

If you're reading this, you already know of the strange and

mysterious land known as the internet. Don't let the naysayers

bring you down with the false claims that they do not make

those anymore. Simply Google "Square Head Bolt"

and a plethora of bolt manufacturers and suppliers should

magically appear.

Brand

new guards with ledger plates. The new tapered bolts for the

guards came

with

new plain hex nuts, but the original nuts were flange nuts.

Flange nuts seem

to work much better, so I replaced them with these hardened

steel flange nuts.

Another

good resource for parts, even parts that are legitimately

not made anymore, is Ebay. A broken lever, wheel, seat spring,

etc ... can all be found on this site ... though patience

is key. You might not find the part you need, right when you

need it, but if you wait, and keep checking, mostly likely

you'll see it pop up. When restoring anything, usually fixing

it fast and fixing right have two different results.

While

we're talking about nuts and bolts, here's a photo of the

combination wrench that came with the No. 7 mower.

- - - - - - -

The

Pitman

The

pitman is a wooden arm that operates that mower. As the gears

turn, they turn the flywheel on which the pitman is mounted.

The pitman moves back and forth, moving the knives back and

forth between the guards.

Some

have asked why the pitman is wood, and why it couldn't be

made of metal? The wooden pitman is actually a safety feature.

If the mower snags on a rock or other hard obstacle, the pitman

is designed to break before metal gears or shafts can be damaged.

Even

so, the pitman needs to be made of a durable hardwood. White

oak, hickory, and even hedge apple or bodock has been used

for pitmans. Pitmans are usually available online for around

$10 or so. In my case, I happened to have a scrap piece of

white oak sitting around my shop that was practically the

right size (I trimmed about 3 inches off). And size IS important.

Different

machines have different pitman lengths. IT MUST BE CUT TO

THE EXACT SIZE. A pitman that is too long for your machine

will be short-lived, and most likely will result in broken

knives and bent parts. Always test your pitman before putting

the machine in operation.

-

- - - - - -

08-21-2017

-I painted the outer wheels today (while taking in the total

solar eclipse).

The photo actually makes the inner wheels look more white

than they

actually are. International White is actually more of a cream

or almond color.

08-25-2017

- Reinstalled the raising levers, seat spring, and pitman,

As

well as all the cotter pins. I also painted the seat, but

that will need

to

dry a few days before installing. Painting takes time.

-

- - - - - -

I

had originally planned on using my sassafras tongue that I

had cut at a local sawmill, but I ran across an ash tongue

which I bought from an Amish gentleman. With the sassafras

tongue still green and needing to season, I've decided to

use it on my other No. 7 mower or maybe my No. 6.

Here's

the new ash pole

The

ash pole is something that will be hard to find very soon.

Ash is now quarantined due to a beetle infestation, and it

looks like the species may go the way of the American chestnut.

After some sanding and shaping, I'll put a coat of varnish

on the tongue. A new mower would have had the tongue painted

ochre, but replacements, like this one, usually came natural.

Most farmers didn't repaint the tongues, though some, like

my grandfather, may have coated the wood with old motor oil

to help preserve it. I'm going to keep the natural wood look

with a clear finish.

The

tongue or pole with its first coat of varnish.

-

- - - - - - -

The

Oil Can

Since

Hurricane Harvey has moved over our house, I'm working inside

today. So, I decided it would be a good time to restore the

No. 7's oil can. This was a little bit of a complicated restoration.

I found

an original oil can, but the old paint was very faded and

the logo was barely visible. First, I cleaned the can of all

the old paint and years of oil residue, then buffed it with

a very fine steel wool.

Next,

I painted the white field with a lacquer Harvester white paint.

After

drying a few days, I wet sanded the painted area with a 800

grit sandpaper, then applied the logo and stripes using a

special transfer paper. I had found the logo online, but had

to basically redraw it in Photoshop to get the resolution

I needed for the transfer. On the back of the original can,

the dealer's name was so degraded I couldn't read it anymore,

so, I simply added the name of my own business to the can.

I reversed the image, then printed it on the special paper

using a laser printer.

The application

of the transfer is a little intricate, using a special adhesive,

then heating with a heat gun, applying the graphic, then a

series of rubbing the piece, heating, and washing with water.

Afterwards,

I applied a clear lacquer to help protect the logo. I think

it turned out pretty good.

The

Grassboard Logo

I applied

the "McCormick-Deering" logo to the side of the

grassboard using a water-based polyurethane. I had printed

the logo in reverse on regular paper using a laser printer.

I then applied a thin coat of poly to the grassboard. I then

positioned the logo, face down, on the grassboard and carefully

pushed out any wrinkles or bubbles.

After

letting the poly dry for a few hours, I then wet the paper

with water. Once the paper was saturated, I carefully began

rubbing the paper off of the board. It takes some effort,

but eventually the paper comes off, leaving the ink still

in the coat of polyurethane.

I touched

up any bad spots with a red marker, then applied another coat

of poly to seal and protect the logo. I think it came out

pretty decent. I'll add a red stripe along the top of the

tracker after this dries.

Painting the Pole Iron

Starting

to paint all the hardware on the tongue, which is supposed

to be Indian red. No one sells a Harvester Indian red paint

or has the paint code for the original paint, but as near

as I can tell (from spots of original paint on some of the

parts) Indian red is a bit darker than Harvester red. I found

a paint that I think is pretty close.

-

- - - - - -

Fitting

the Pole

The

No. 7 mower is really coming together now and it's time to

start fitting the tongue or pole. Now, the No. 7 is designed

to accept a square or round tongue, in fact, the tongue I

took off this machine was a round cedar pole. Yes, I said

cedar.

Notice

the domed recess where the tongue mounts.

I know

cedar is no where near the recommended strength for a mowing

machine, but you have to remember that farmers, especially

those that grew up in the Great Depression, used what they

had available. The original pole had obviously broke and the

farmer used the closest thing he had available.

Cedar

is a pioneer tree, meaning that if you scrape the ground clear,

cedar is one of the first trees to reappear and start growing.

The farmer probably had 1,000 of these straight growing trees

to choose from. When his tongue broke, he simply cut a nearby

cedar, trimmed the limbs and shaved the bark, and fitted it

to the mower. It may not have been as nice and strong as a

ready-made oak or ash tongue, but it worked for what he needed.

And, if he was like my grandfather, who grew tobacco and raised

beef cattle, he never grew money trees.

I used a lawn chair to prop up the tongue while working on

it

You can

fit either a square or round pole to the No. 7, but I obtained

a nice square ash tongue from the Amish. The tongue was nearly

ready to go, but with the rounded top to the recess where

the tongue is mounted, I decided to try to make the pole fit

a little better. Being a woodworker, I know that the tighter

and more precise the fit, the stronger the joint will be.

I want to get as much metal to wood surface area as I can.

I decided to round the top of my pole to make a better fit.

This is not necessary, but I think it makes it look nicer

and makes it stronger.

Another

thing was the pole was a little too deep (top to bottom) to

clear the adjustment rod that runs underneath, near the back.

I want as much wood as possible, so I notched out a section

of the pole, just enough to clear the rod.

I notched just the back of the pole to clear the rod

Once fitted

and the holes are drilled, I'll put a coat of varnish on the

bare wood to add some protection. I'll also add the black

decorative striping to the top of the tongue before mounting

it.

- - -

- - - -

Striping

the Tongue

The No.

7 had a black decorative stripes running along the top of

the tongue just past the doubletrees. You can see the stripes

in several illustrations in McCormick-Deering manuals and

publications, but I have yet to find a photo of the stripes.

This is my best interpretation of what they should be.

With no

fancy script or combination of colors, I used masking tape

to mark off the area where the striping should be, then simply

applied a few light coats of black spray paint. Light coats

reduce the chance of bleeding. Afterwards, I applied a couple

of coats of clear to seal the stripes.

You can see the striping in the illustration at the bottom

right

The stripes

were on at least some late model No. 6 mowers, and all No.

7 mowers. The striping was eliminated in 1939 after the No.

9 models were introduced.

- - -

- - - - -

The

Tracker Stick

I made

the tracker stick using a piece of oak on a lathe. I tapered

the stick slightly and rounded the end.

Unfortunately

I don't have any original parts to go by, and I had to make

the metal mounting bracket from scratch. The bracket wraps

around the stick and has two holes for mounting to the board.

The stick pivots on the back bolt, while the pointed end enters

one of three holes, allowing for the stick to be adjusted

in height.

I cut

out the bracket from a thick piece of sheet metal, then, using

a hammer, rounded the metal around the stick. The pointed

end sits flat against the board, so after rounding it, I put

it in a vice to flatten the end. After drilling the holes,

I'll prime and paint this piece red.

The

grassboard is almost finished. I didn't have an original grassboard

to go by and had to rely on old photos and illustrations to

make this one, basically from scratch. I fabricated pretty

much all the metal and cut out the sassafras wood. One thing

I did have was an original John Deere grassboard. I used it

to get the general dimensions and the angle for the grass

stick. There is also a thick metal band running along the

bottom of the board, to help reduce wear. The board attaches

with a bolt and a spring at the end of the mower bar. The

spring allows the board to flex should it hit some kind of

obstacle.

Here's

the finished grassboard with the grass stick attached with

carriage bolts and square nuts. I think it turned out pretty

good. I'll add the spring and attach it to the mower bar.

-

- - - - - - -

Making

the Yoke

With the

grassboard finished, I turned my attention to the evener.

The evener, or yoke, is the wooden bar mounted on the front

end of the tongue. McCormick-Deering's literature refers to

this bar as the evener, but later calls it the yoke. The middle

bar of the double tree is also called an evener by some, so,

as not to confuse the two, I'll refer to the front evener

as the yoke, and the middle bar on the double tree as the

evener.

I have

the original yoke for the machine, but like so much else on

the mower, it had seen better days. The yoke had seen many

hours of use with the wood worn around the ends, and the metal

rings and eye bolts worn thin. I could have restored the original,

but I decided to just make a new one.

Luckily,

last winter, I had a white oak tree fall on my property. This

gave me a good source for a piece of wood that would need

to be three inches thick. After finding a nice, straight branch,

I cut it and stripped off the bark. I was going to have to

turn the yoke on a lathe, but the piece I needed was about

four inches longer than what my lathe could hold. Fortunately,

I had a solution.

I found

my wood lathe at an auction for $5, and I figured the price

was so low, I actually bought two. The reason I wanted two

lathes is just for this type of problem. When turning bed

posts, and high-back chairs, I would need a long lathe so

I wouldn't have to turn them in two pieces. I tore the cheap

lathes apart and found that the reason neither worked was

that whoever owned them before had never bothered to lube

them. After oiling them up, and some gentle persuasion, both

worked perfectly. I built a A-frame bench long enough for

both lathes, then simply bolted them on, end to end. This

gave me a long lathe track, allowing me to turn long pieces.

A little

time on the band saw, and with a draw knife, helped me balance

out the log. Then, I mounted it onto the lathe. I rounded

the wood at three inches, then worked from the middle to taper

it at both ends. The yoke needs to be the same length as the

double tree evener, with the metal rings on the yoke lining

up with the bolts on the evener.

I discovered

that finding three or four inch steel rings is actually pretty

hard. The biggest rings that most tractor or farm supply stores

have is two inches, way too small for my needs. Once again,

the Internet came to the rescue. I found a source for non

welded three and a half inch steel rings online. I need them

to not be welded so I can install them onto the new eye bolts.

Once installed, I weld them together myself.

Painting

the Raised Lettering

There

is really no other way to do this, except for with a very

small brush, and a steady hand. Yes, the raised lettering

on the mower body was highlighted in International white.

It's not as hard as it might look, but it takes a long time

to do it right. After I did this, I sprayed the whole body

with a clear coat for extra protection.

Finally

Complete!

Well,

here it is! If you ever wondered what a McComick-Deering No.

7 Mower looked like when it was brand new, here it is. So

many today only see these as lawn ornaments or mailbox mounts.

This mower is complete with its correct wrench, oil can, decal,

lettering, and the correct Red, White, and Blue color scheme.

The tongue is ash, while the yoke and pitman are made from

white oak. The grassboard is sassafras.

The only

thing that would not be considered accurate is that the tongue

and yoke are natural with a varnish. Originals would have

been painted ochre, which is a yellow-orange color. Most replacement

parts wouldn't have been painted, and I think the natural

looks better.

10/06/2017

- Thanks for stopping by twodawgs1@dtccom.net

|